Manufacturer Hydraulic Cylinders

We LHS sales team believe , to first understand the customer's needs then to know the working application then the usage , working stroke , acting load , working environment , repeatability of working i.e no of working cycles , by which we can help to choose the right type of cylinders that can be used , like mounting type , operating pressure , types of seals to incorporate to give max life of the cylinders , material selection in making the hydraulic cylinders. Partnering with early in the design phase saves engineering teams time and money while ensuring the final system does its assigned duties as efficiently as possible for as long as possible

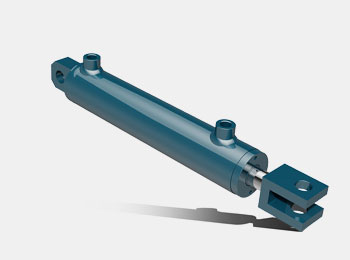

Our customer expects hydraulic solutions from us , so we have designed various models with stress analysis of cylinders over the machinery in our latest CAD-CAM software for demonstrations.

TYPES OF HYDRAULIC Series

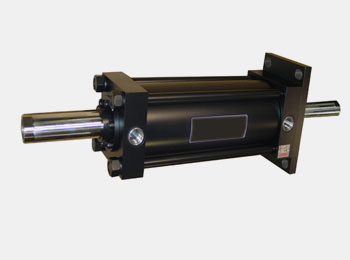

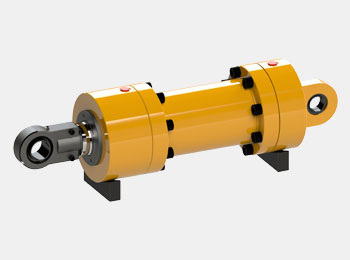

We can design and manufacture for OEMs / single machine manufacturer / in-house machine building for particular applications / vehicle mounted / due to which we have variety in manufacturing any type of cylinders some are the following list of cylinder types that we manufacture In tie rod as well as welded type and some special type:

Manufacturing Facility permits us to manufacture the hydraulic cylinders with specifications :

- Capacity : upto 700 Bar and upto 500 Ton

- Stroking distance: Upto 5 meters

- Speed : upto 1 m/sec

- Temperature: −54°C to 260°C , in special cases we can go upto 500°C

- Mounting styles [Front - intermediate - Rear ] : Flanges ; Trunnion , Clevis , Shoe type ; Pivot ; Side , any customization available

- Honed tube Bore Size : upto 450 mm

- Piston Rod Size : upto 400 mm

- Piston Rod end : Threading / Pin / Step / Plane

- Piston Rod : Grounded and hard chrome plated

- Material : Stainless steel [SS] , Alloy steel , aluminium , brass , titanium

- Inbuilt optional Cylinder configurations: Both end cushioning , Non return valves , check valves , air vents , spring return , safety valve and customization available

- Cylinder tubes :Plane with ports ,Ports welded oil tubes ,One end plugged and customization available

- Seals: Being hydraulics manufacturer, we offer seals compatible with a range of temperatures and fluids and can help choose seal materials that meet application requirements.

- All Components are CNC- VMV produced Subject to quantities

We cater to customers who want to have spare hydraulic cylinder due to various reasons like :

- Old machines ,

- Having multiple same type of machines, which had similar types of hydraulic cylinder working, to reduce the down time.

- Replace the old type Hydraulic cylinders with new type of sealing

- Zero tolerance in production loss

- No support from OEM

- OEM supplied cylinder is faulty in design and manufacturing errors